3221石材雕刻机

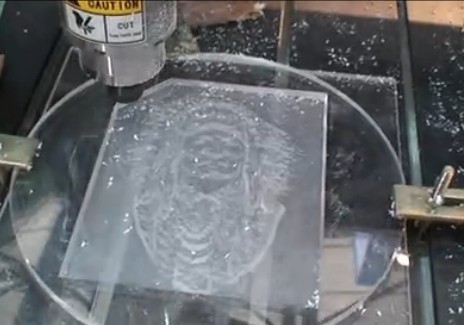

3轴木工雕刻机可以用于雕刻和切割一些材料:实木,石材,金属,玻璃,泡沫,PVC,亚克力等。 产品应用于家具,厨具,橱柜,模具制造,航空航天,轨道交通,电子等。

雕刻机,

CNC Router, CNC Router Machine, Wood Carving Machine, CNC Machine, Engraving Machine; used to engrave and cut on wood, MDF, PVC, foam, acrylic, stone, marble, aluminum;

7' x 10.5' stone CNC Router

This machine is compatible with many common CAD/CAM platforms including.If you are wanting a more in-depth overview of the design software used with machine, please contact with us and watch video on how to get started with CNC.

Increase your shop’s production with this value-packed CNC machine.

The complete and easy-to-read manual makes it easier to assemble and maintain your machine.

Like all of the computer numeric controlled machines, the machine comes with a 3-year warranty covering parts and assuring the unit is free from factory defects (Consumables are not covered by the warranty); we have 21 years Customer Service experience and professional Technical Support Teams.

Parts and accessories for the CNC machine may be available online and shipped by fedex from china.

Made in an ISO 9001 factory

CE certified

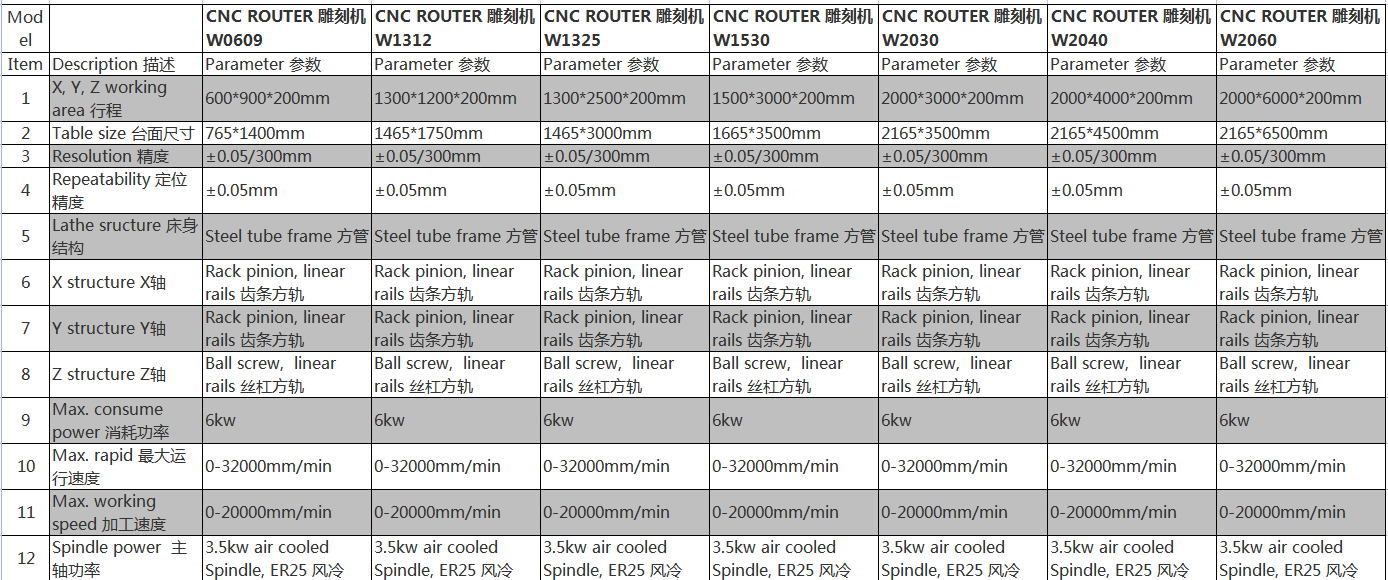

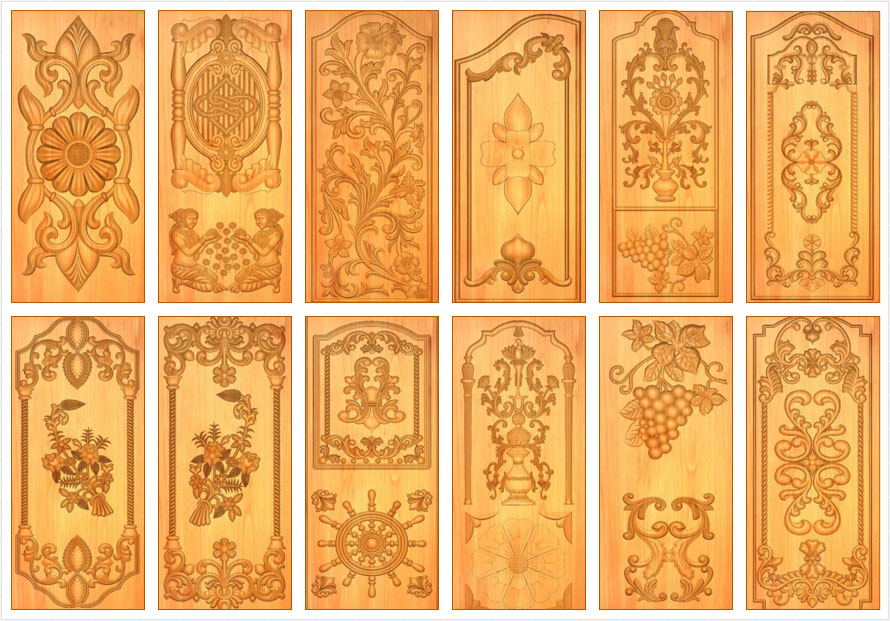

SPECIFICATIONS:

Spindle motor: 14.74HP 11KW, 220V, 3-phase, 3000rpm

Axis motors: stepper or AC Servo Motor

X-Axis working size: 2135mm

Y-Axis working size: 3200mm

Z-Axis working size: 400mm

A axis 0-90 degree

C axis 360 degree

table turning angel 0-80 degree

max weight for turning 800kgs

saw diameter 450mm

saw max cutting thickness 100mm

XY- rapid speed: 56m/min,

Z- rapid speed: 20m/min

Cutting accuracy: +/-0.05

FEATURES:

English Step control system

water-cooled spindle motor

Tool touch-off pad for quickly setting Z-axis height

Helical rack-and-pinion X- and Y- gantry travel, Z ball screw;

Description:

This stone CNC machining center can cut quartz, marble, granite, and rock slabs with a powerful saw blade. It combines a saw blade and CNC router tools to achieve multiple advanced functions. For example, cutting and milling straight and inclined edges, chamfering, cutting arc edges, polygon, edge milling, etc. The 5 axis bridge saw gains popularity in the stone processing plants, kitchen countertop processing, background wall profiling, and other fields.

Features:

1. It adopts 5 axis bridge cutting head, which is independently researched and developed and adopts the cast rotating bracket. This ensures good stability and flexibility during operation.

2. This bridge saw uses a high-precision RV reducer, ensuring better rotating precision of the cutting head.

3. It has built-in CAM software in the control system for the convenient of drawing designs and programming. Besides, it’s easy to learn the software to make designs.

4. The worktable can flip automatically up to 80 degrees, reducing human labor and facilitating the unloading process.

5. It is capable of cutting lengths of up to 2800mm, widths of 1200mm and thicknesses of 100mm.

6. The table automatically tilts up to 80 degrees. And the spindle is automatically rotated 90° or 360°by hydraulic pressure.

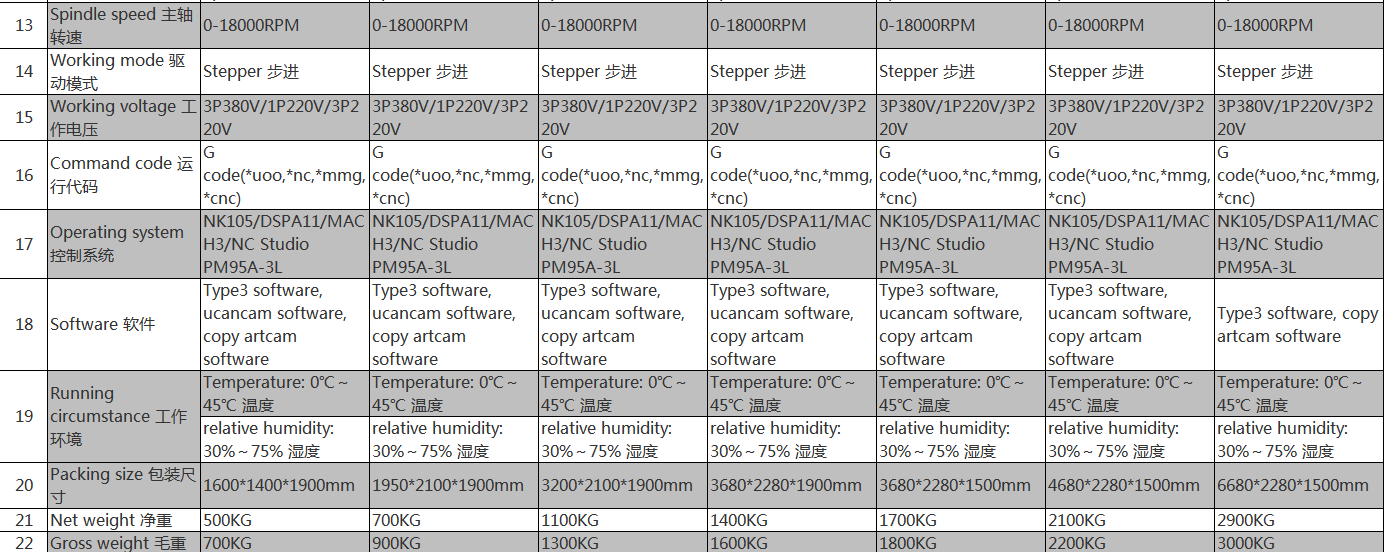

CNC Stone engraving machine is a CNC stone router, we also call it CNC marble engraving machine, it is good at engraving works on stone/marble, and is also able to carve or cut stones with different bits;

CNC Stone machining center will have a better efficiency on stone carving and cutting, if you have a lot of need on carving and cutting, and want to work high efficiently, considering a stone machine center.

Application:

The 5 axis CNC stone bridge saw can process quartz, marble, artificial stone and slabs in regular and irregular shapes. It is good at cutting, milling, chamfering and edging. And it can realize countertop cutting, bridge cutting, roman column cutting, arc line cutting, concave-convex cutting, etc.

The automatic stone cutting bridge saw can process products of sanitary ware, stone furniture, interior decoration, etc. For example, wash basins, bathroom countertop, stone tables, dinning tables, kitchen tables, etc.

产品目录

联系我们

- +86-531-88586516

- +86-531-88586517

- +86-18653142760

- [email protected]

- maxryli

- +86-18653142760

售前客服

售前客服